The Photovoltaic Performance Modeling Collaborative (PVPMC), facilitated by Sandia National Laboratories, serves as an essential forum for PV professionals aiming to enhance the accuracy and rigor of PV performance models, including those that specifically evaluate solar tracker impact on energy production. This collaborative effort is crucial for developing reliable models that assess current performance, predict future energy yield, and influence investment decisions within the solar industry.

This year, ARRAY was honored to share our knowledge and leadership in modeling solar tracker impact on energy production, highlighted by a key presentation from one of our Senior Engineering Managers, Kendra Conrad, on the “Energy Impact of Different Solar Tracker Wind Stow Strategies.”

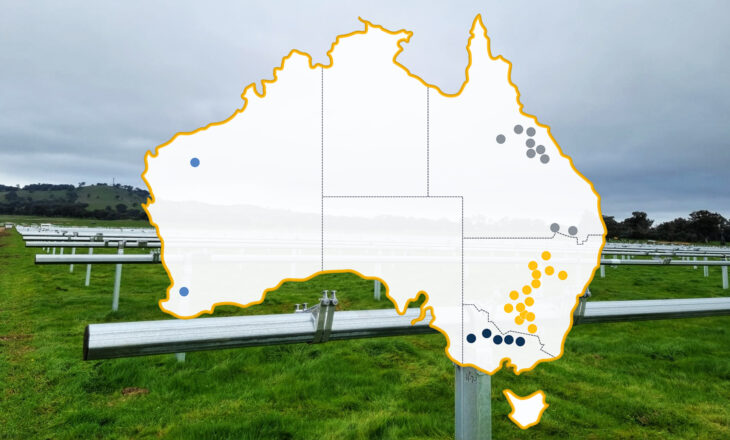

Kendra’s talk on wind-stow energy loss drew a crowd and kicked off some great discussions. She introduced ARRAY’s proprietary modeling methodology and showed how ARRAY DuraTrack® trackers’ mechanical passive wind stow solution yields minimal energy losses—peaking at just 0.14% across 12 diverse locations. In contrast, sensor-based active stow strategies exhibited significantly higher losses, with a maximum of 4.2% for the same sites.

The enthusiastic feedback and questions that followed underscored the importance of this innovative work. Kendra’s insights not only illuminated the superior efficiency of our passive wind stow solution but also highlighted the substantial advantages it offers in optimizing energy retention.

So, to continue the momentum, here are two questions we tackled and three major insights we took away from PVPMC 2024.

ARRAY Senior Engineering Manager, Kendra Conrad, presenting at PVPMC 2024.

2 Burning Questions from PVPMC 2024

1. Is ARRAY’s Mechanical Passive Stow a New Feature?

At PVPMC 2024, we fielded a lot of questions about the advantages of our DuraTrack tracker, especially about its passive mechanically activated stow feature. Kendra explained how ARRAY’s technology has evolved continuously to meet the high demands of today’s solar infrastructures, ensuring top-notch performance and longevity. Our patented, safe, passive wind stow technology is a fundamental component of the latest DuraTrack version and future iterations.

What sets ARRAY’s wind stow technology apart?

Unlike traditional sensor-based active stow methods, which rely on the control system functioning during adverse weather and can cause significant energy loss, our technology offers a more reliable solution. It is designed to protect your equipment from wind damage without sacrificing energy output. This innovation is a true game changer for our customers, aiming to enhance both equipment reliability and energy yield.

2. How Do Individual Rows Stow in the Linked Architecture?

A focal point of Kendra’s talk was the innovative mechanics behind ARRAY’s linked architecture, which is crucial for reliable solar tracker operation in adverse conditions. So, what exactly is a linked architecture, and how can individual rows still stow during high wind events?

Our linked architecture enables multiple rows of solar panel trackers to rotate together as a single unit. This design can be especially cost-efficient and reliable for large utility-scale solar installations. By orienting a large number of solar panels with just a few motors and controllers, our architecture strives to maximize efficiency and minimize costs.

Having a strategy to deal with high wind events is critical to solar tracker design. Our DuraTrack trackers feature a torque-limiting clutch on every row, which mechanically activates during high winds. The clutch automatically stows the rows where the mechanical thresholds have been exceeded to the nearest maximum tilt.

In this optimal position, mechanical stops on every pile transfer the wind load directly to the ground, ensuring maximum protection. Stowed rows act as wind barriers for the rows behind them, allowing the unstowed rows to continue tracking normally even during high winds. This can drastically reduce downtime and energy loss, as only a small fraction of the rows need to stow.

Additionally, this stow position is ideal for hail protection, linking seamlessly with our ARRAY SmarTrack™ Hail Alert Response to offer superior defense against hail damage.

3 Key Takeaways from PVPMC 2024

1. Acknowledgment of ARRAY’s Collaboration with Labs and Universities

Our commitment to advancing solar tracker technology by collaborating with labs and universities garnered positive mentions multiple times during the conference.

A few mentions that stood out were:

- Jim Crimmins of CFV Labs proposed using ARRAY DuraTrack trackers in their outdoor yard to build physical twins of utility installations. These reference arrays will aid in degradation monitoring. CFV Labs, an ISO-accredited solar test laboratory in New Mexico, has worked with us for over a decade. In 2019, we built a DuraTrack installation to study tracker design’s impact on bifacial systems.

- Dr. Ana Dyreson of Michigan Technological University shared results on the different snow-shedding strategies they have tested using ARRAY DuraTrack trackers at the Michigan Solar RTC. The Michigan Solar RTC is part of the DOE-funded Regional Testing Center program. ARRAY had built a DuraTrack installation at the Michigan RTC back in 2022 to demonstrate the reliability of our trackers in high-snow areas.

These mentions reflect the collaborative relationships that we have built over years, working together with industrial and academic partners to advance the solar tracker technology.

2. Heightened Interest in Hail Mitigation Strategies

The robust dialogues around hail mitigation strategies underscored the industry’s urgency in addressing weather-related challenges, with ARRAY at the forefront of developing risk-mitigation technologies. Even talks that did not mention hail—including Kendra’s—received questions related to hail. Many conversations focused on the massive damage that a solar farm in Texas suffered in March earlier this year.

So, what’s ARRAY’s strategy for handling the unpredictability of hailstorms?

ARRAY offers two primary solutions to help mitigate the risk of hail at your site:

- Manual Hail Stow Solution: This allows site operators to stow all DuraTrack trackers to a safe position (maximum tilt) with a single click on the user interface or with a manual switch on-site.

- ARRAY SmarTrack™ Hail Alert Response System: This system automatically triggers the safe-stowing action when hail is forecasted for a site, removing potential human factors from the hail mitigation plan.

These solutions ensure your site is protected against hail damage, enhancing the resilience and longevity of your solar installations.

3. Growing Concern Over Equipment Availability

The conference discussions highlighted the critical importance of equipment availability in accurate energy modeling—a factor now recognized as essential for understanding and resolving underperformance of utility PV power plants. Participants discussed how to correctly incorporate equipment availability in the energy models to improve the accuracy of P50 and P90 values used for project development and financing.

At ARRAY, we set ourselves apart in tracker availability through innovative features that enhance uptime and energy production. The simplicity of our DuraTrack linked architecture, which includes significantly fewer parts per MW than competitor tracker products, results in higher uptime. Plus, DuraTrack’s mechanical passive wind mitigation limits the frequency of stow events, which can result in higher uptime and minimize wind-stow energy losses.

PVPMC 2024 provided a dynamic platform for ARRAY to showcase our dedication to pushing the boundaries of solar tracker technology. We hope the industry adopts the modeling methodology Kendra presented to accurately include wind-stow energy losses in energy production estimates.

We invite industry professionals to engage with us further, share insights, and discuss future collaborations. For more information on our technology and services, or to schedule a detailed discussion, please visit our contact page.

Click here for other articles by this author

Click here for other articles by this author