A primary goal of utility-scale PV power plants is to optimize power production. To achieve that goal, manufacturers are turning to increased module sizes in the hopes of increasing module power. This can bring lower levelized cost of energy, lower balance of system costs, faster installation, and, sometimes, even reduced land costs.

With 650W+ modules now available, it appears that large module formats are here to stay, particularly when manufacturers can create them in comparable time to smaller modules.

This is promising in terms of pure module power – but that doesn’t mean there aren’t implications to navigate. How will trackers accommodate these large format modules? How will inverter choices and system layouts change? Will new construction codes crop up to inform design? How will insurers react? And on top of all that, there are structural and mechanical engineering considerations, especially in high-wind environments.

This all adds up to a clear need for industry collaboration between developers, module manufacturers and mounting system providers to work toward a common goal of efficient standardization. This collaboration will help prevent significant cost increases in balance of system, installation and soft costs that could negate the benefits of technological progress.

Breaking Down the Site-Wide Costs Associated with Larger Solar Modules

Module size alterations can potentially lead to improved cost per watt for PV plants, lower labor costs associated with installation, and elevated row-by-row production. They also have the potential, though, to introduce elevated mounting system costs, including trackers.

Because of this, informed design decisions during the planning phase can help avoid these higher costs and lead to better optimization of entire systems and sites.

For example, increasing structural designs to accommodate higher loads levied by larger modules could potentially interfere with the power generation capacity of the back side of panels, and more support structure, in general, could result in higher freight costs, extended installation times, and more.

That means that weighing the potential benefits in terms of production against these costs is critical, as is thoroughly assessing the risks associated with larger modules in terms of resilience in the face of high winds and heavy snow loading.

Collaboration as the Way Forward in Navigating Increasing Module Sizes

As it stands, it will be difficult for the solar energy industry to continue producing larger and larger modules without seeing corresponding increases in balance of plant and insurance costs.

Other considerations are also important, such as the aforementioned impact of snow loading due to the sheer surface area increases found in larger modules and the changing impacts of shading, torque, wind, and more.

Dave Sharratt, VP of International Business Development at ARRAY mentions that “There could be some unintended consequences if all the players in the utility-scale PV ecosystem operate in silos about their advancing technologies. For example, structures that are built for lower wind speeds may not be able to handle larger modules in regions with extreme weather. Also, larger modules logically may require more support structure. This increases installation time, freight and logistics costs, and overall a higher build cost for EPCs. Rigorous analysis past simple OpEx is needed to determine best-in-class components that are compatible to ensure seamless integration and plant resiliency.”

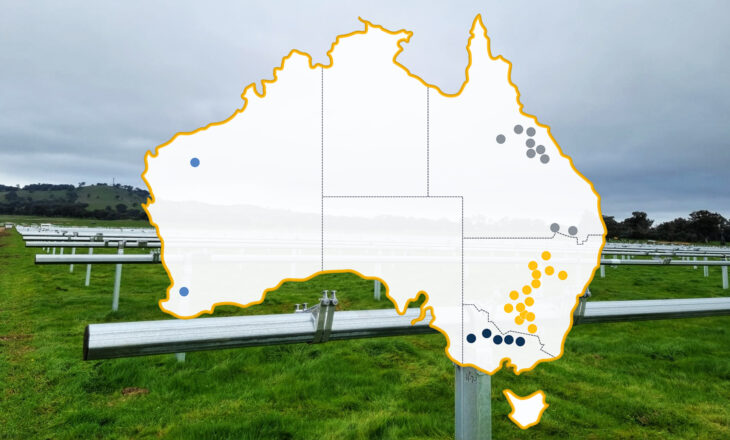

ARRAY is committed to helping foster the collaboration between developers, module manufacturers, and mounting system providers. This collaboration is critical to avoid unexpected increases in PV plant project costs.

Dr. Mengyuan Li, ARRAY Technologies’ Business Development Director for Asia, stresses that “There’s a positive and increasing trend of accelerating engineering collaboration between module manufacturers and structure providers like ARRAY to standardize design goals to ensure these larger modules don’t simply create additional expenses in the balance of systems or project insurance. Finding the lowest LCOE for investors needs to be a collective effort through the value chain.”

In conducting a study to better understand the relationship between larger PV modules and site-wide costs, ARRAY found:

- Lower module weight leads to longer rows, which can significantly decrease tracker costs across the plant

- Longer modules typically generate more power per unit length along the tracker row. In areas with relatively low wind and snow loads this is often a great solution to reduce tracker cost per Watt. But on sites with relatively high loads the longer module transfers more of these loads to the tracker structure and increases the number of required foundations and weight of module support components

- Larger modules typically generate more power per tracker row, but it may be at the expense of higher costs in the tracker structure and module support components

- Modules with large surface areas and relatively thin frames will require heavier clamp solutions to offset deflection

- Module efficiency is the most direct correlation between module characteristics and reduced tracker costs

- Modules with relatively low power but high efficiency resulted in lower tracker costs

- Output power alone correlates poorly with tracker cost

Array’s engineering experts act as trusted advisors to our clients, helping steer developers and financiers through decisions that require a working knowledge of the quickly evolving trends in utility-scale solar.

Array’s team goes to great lengths to ensure that module support and clamping considerations result in the minimum amount of shading and the ideal distance between module backside and the torque tube, helping optimize site design. This trend is simply one in a long line of advancements and innovations we have seen during our 30+ years of experience in utility-scale solar. Our primary goal continues to be to help each and every developer, EPC, and asset owner achieve the best possible outcome via the most cost-effective and productive solution.

To learn more, contact us today, or download your copy of our recent white paper “Larger PV Modules: Breaking Down Site-Wide Costs” by clicking HERE.

Click here for other articles by this author